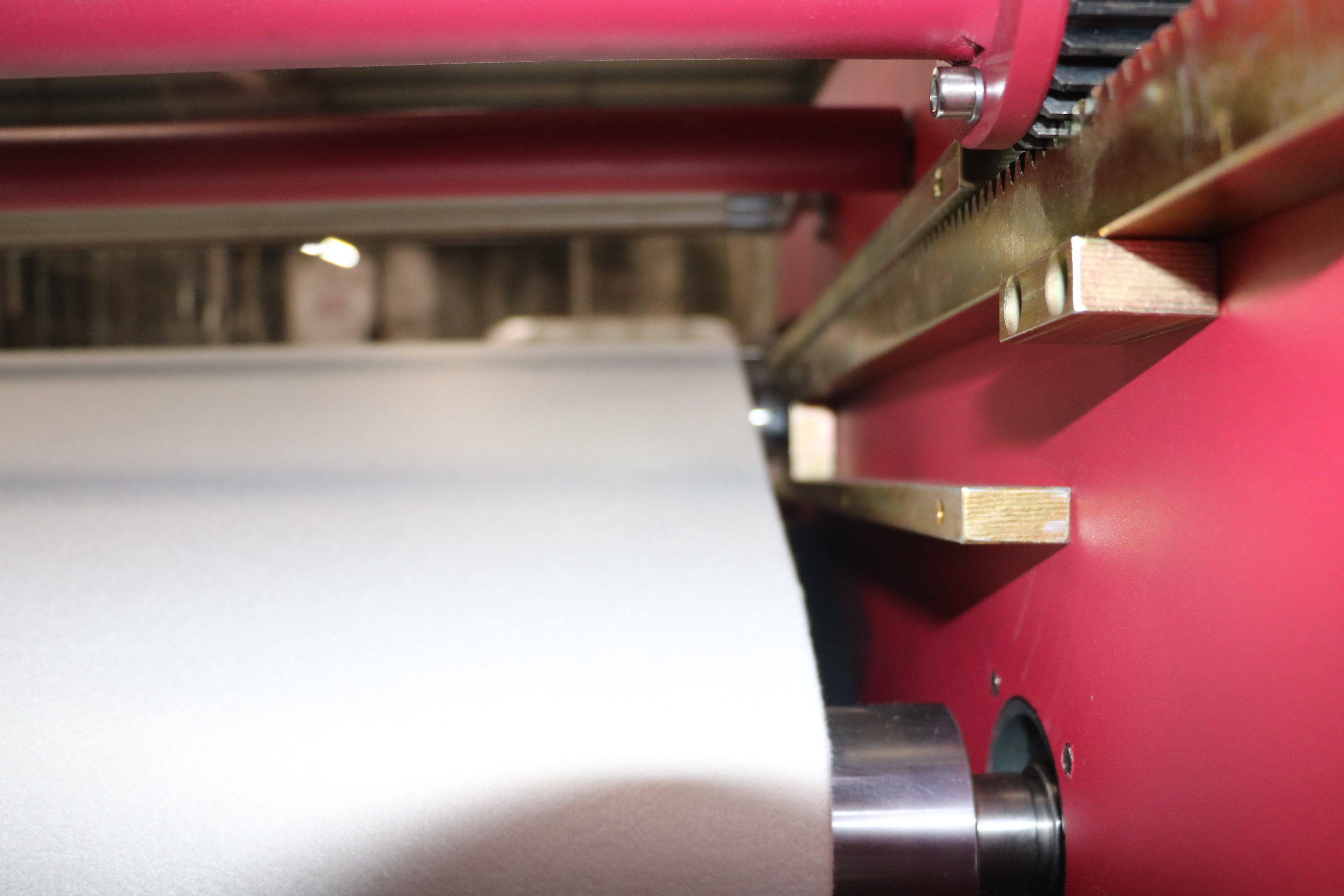

Roller printing machine blanket predetermined type of instructions for use

Both the drum type Heat transfer machine and the Ribbon transfer

machine use a multi-layer fiber structure containing DuPont's patented product,

the flame retardant material Nomex®, which has the characteristics of not

burning away from the flame and not melting. These properties of Nomex® come

from its special molecular structure, which means its flame retardant

protection is permanent. Due to cost reasons, all blankets do not use 100%

Nomex. Blankets are therefore not absolutely flammable, and high temperature

continuous heating is still largely avoided during use.

Nomex®

is a special material that continuously absorbs heat and causes changes in

surface properties.

Due to the

difference in tension and temperature between the production process of the

felt and the actual use of the machine, the new Blanket must be subjected to a

predetermined type of process before it can be put into formal production. We

recommend that the predetermined type of flow be as follows.

The Blanket

is first loaded into the machine and put into a pressurized state, and the

predetermined operation is carried out in the forward rotation of the machine (the direction of rotation of the official production) and the temperature and

time listed in the following table.

(If the blanket is deviation, try to

avoid the adjustment . If it needs to be corrected, it should be decompressed

before operation)