90 g high ink-carrying capacity roller sublimation heat transfer paper

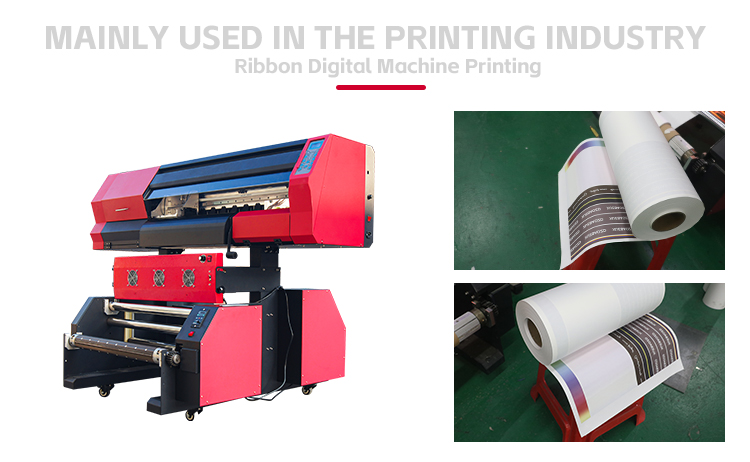

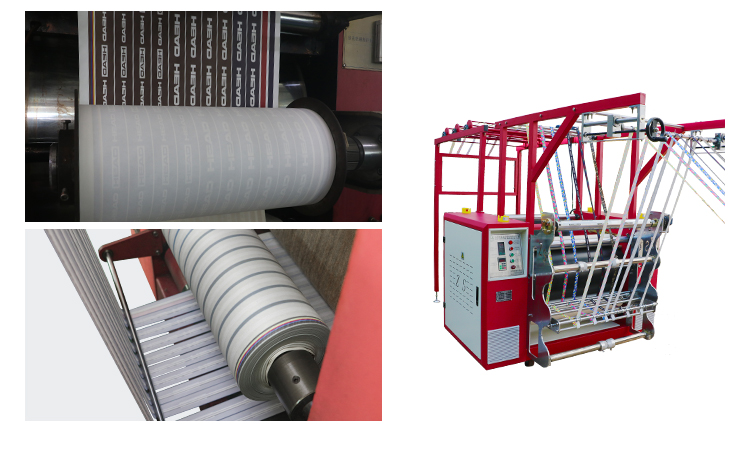

1.what is the sublimation heat transfer printing?

Sublimation heat transfer printing is a portrait, landscape, such as text by using a heat transfer ink, inkjet printer to print image reversal way on the sublimation transfer paper, and then the machine heated to about 200 ℃, sublimation heat transfer ink will be in the form of gasification into substrates on the paper , so as to put the paper on the vivid images to transfer to textiles, porcelain, porcelain, porcelain plate, metal material such as a new technology.heat

2.Suitable for our products is Epson inkjet pinter.

Epson all models are suitable for wide inkjet printers:Roland、Mutoh、Bncad、Mimaki

Epson 3000、4000、4000HS、7600、9600、10600 ect.

3.Must use special sublimation heat transfer printing ink:

This kind of made of disperse dye inks in the heat transfer high temperature will produce sublimation and substrates with dyeing.

The sublimation ink is unfavorable and plug nozzle and with good quality color and good stability.

4.Adjust the suitable concentration of color:

Adjust the concentration of the color in the computer.

Avoid the ink is too dry.

Need to check the effect of thermal transfer after adjustment.

5.Adjust the hot-pressing temperature and time of right:

The heat transfer temperature range about 180-180 ℃, time range about 10 to 30 seconds

Before the formal mass transfer should make small decision optimum process parameters;

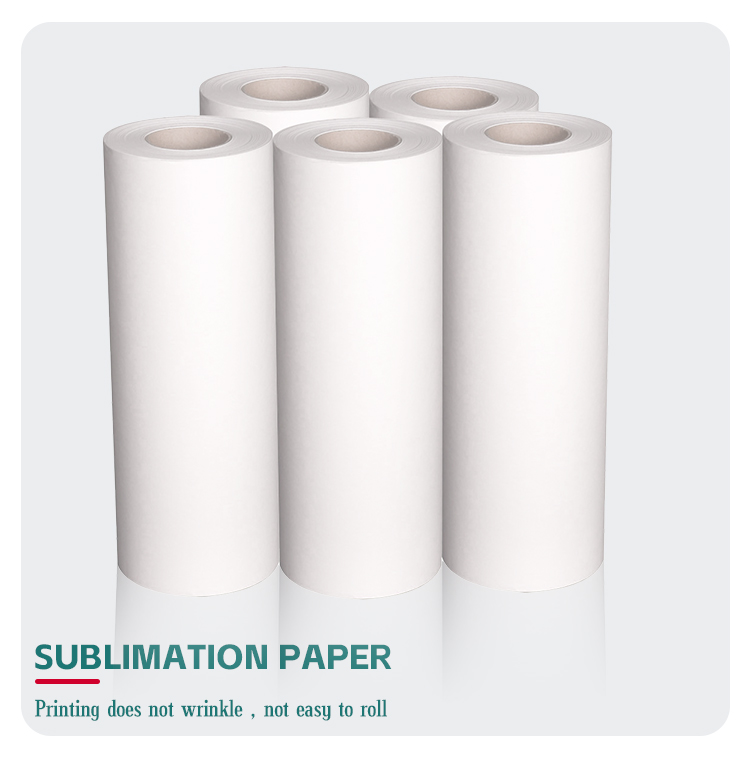

6.The advantages of the sublimation paper:

High quality heat sublimation transfer printing graphic colorful, rich, its effect is equivalent to that of the printing

The heat transfer products are durable, the image will not fall off and crack and fade.

|

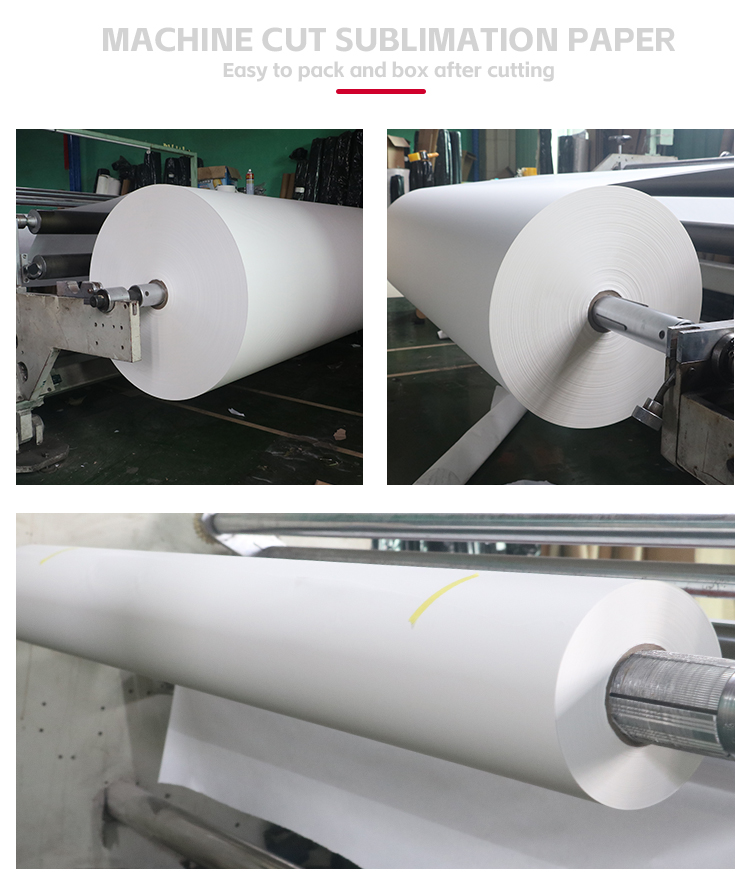

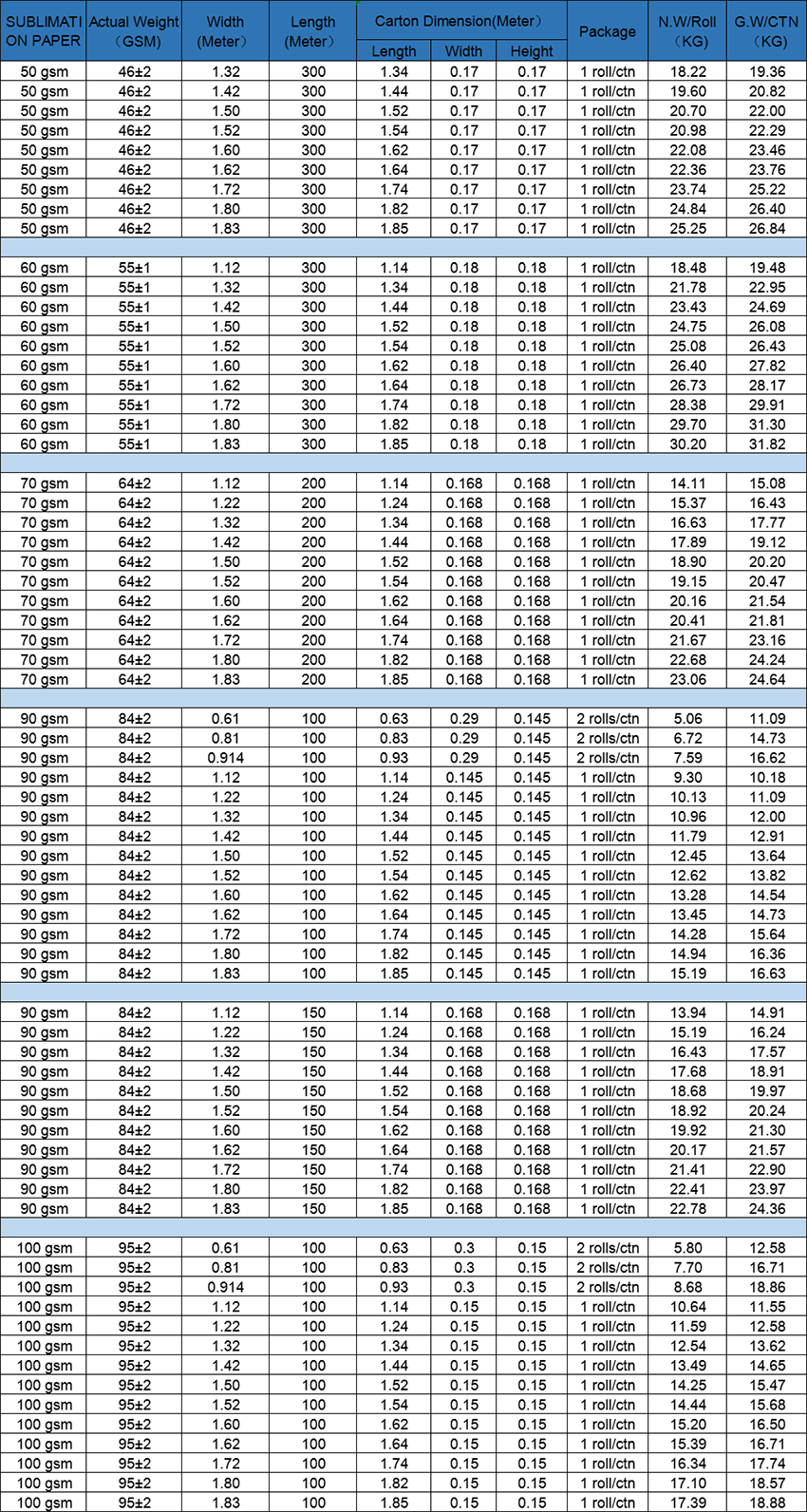

Roller sublimation paper |

||||||||||

| thickness |

90 g |

|||||||||

| Length |

100 meters one roll |

|||||||||

| Width | 21 cm | 30 cm | 42 cm | 48 cm | 61 cm | 91.4 cm | 118 cm | 130 cm | 160 cm |

162 cm |