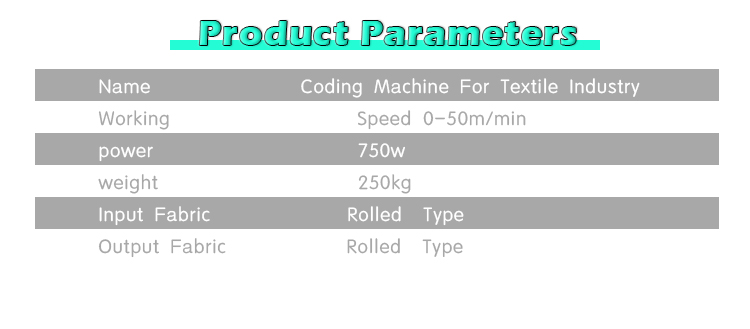

1.Infrared automatic monitoring of cloth placing system and cloth feeding button to avoid stretching and deformation during cloth operation.

2.Infrared automatic edge alignment system to ensure that the cloth edges are neat.

3.Cloth rolling, cloth laying and cloth inspection are equipped with independent motor drive. The distribution motor can be stopped separately to accept the scattered distribution, so as to save power and realize multiple modes.

4.Automatic reset and automatic shutdown after cloth inspection.

5.Configure automatic cloth spreading (shifting) roller to make the cloth roll smoother.

6.It is driven by the frequency converter of famous factory, and the cloth tension or no tension can be adjusted arbitrarily. The cloth inspection speed is adjustable from 0 to 50m / min.

7.The cloth can be rolled back and forth to facilitate the rewinding and re inspection of leakage detection cloth.

8.It is equipped with high-quality transparent materials and strong up and down lights, so that the running cloth can be seen at a glance.

9.Configure high-precision gauge to accurately record the quantity of cloth.

10.The device has the functions of correcting and reversing cloth rolling.

11.Humanized design: it is designed in combination with ergonomics to reduce work fatigue and improve work efficiency.

12.Maximum diameter of unwinding: 35cm.

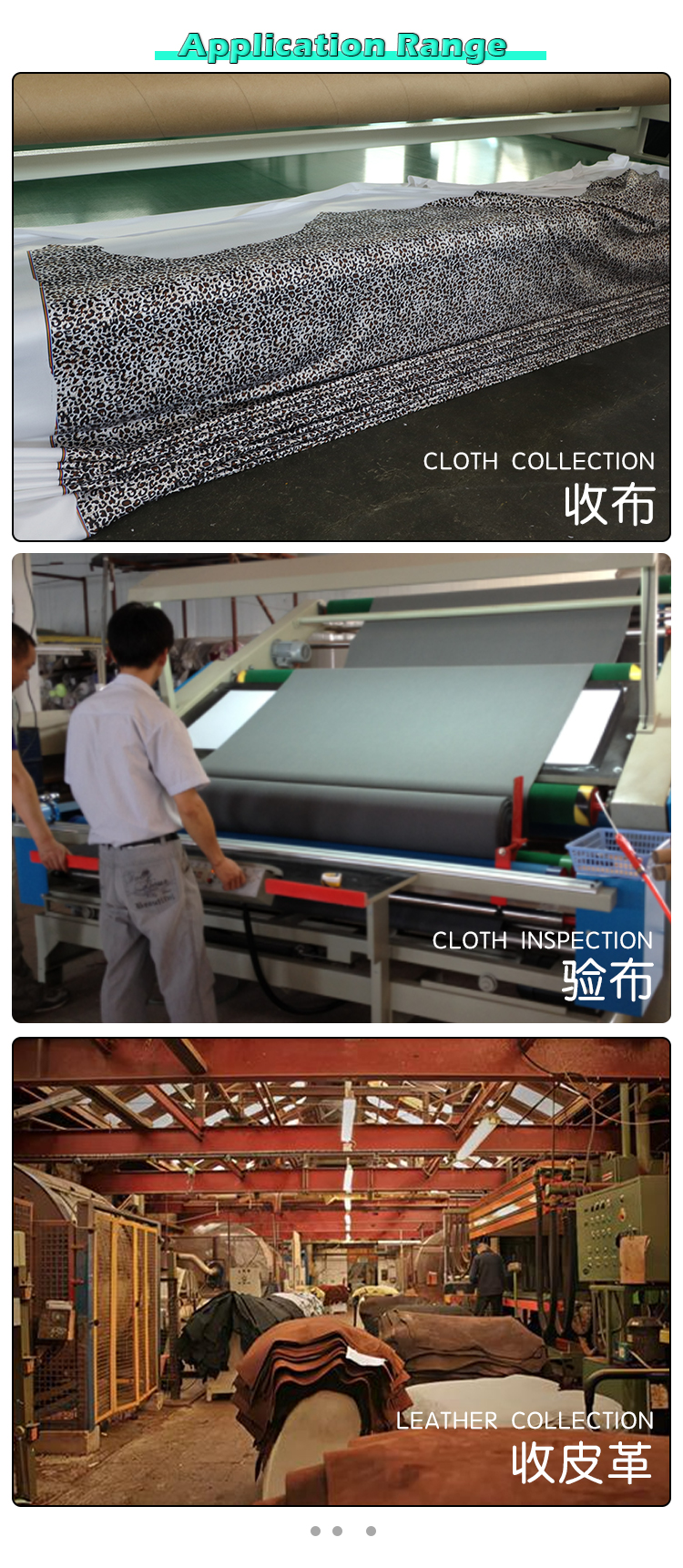

It is suitable for cloth inspection, rolling and coding of knitted fabrics, woven fabrics, leather, PU, PPC and other products.