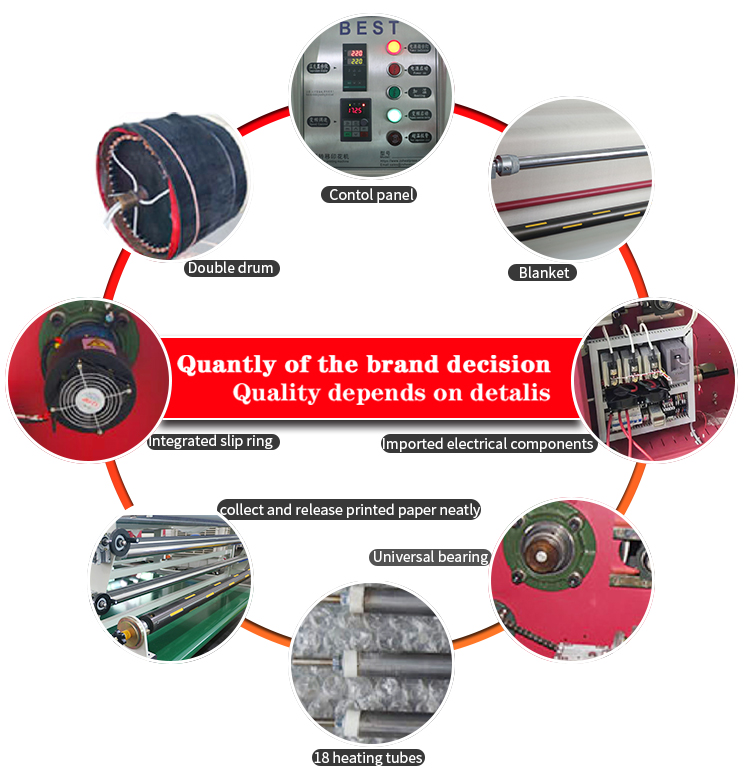

Main features:

1. DuPont Blanket : Blanket is made of American DuPont materials, 10 mm thickness, good transfer effect, long service life.

2. Single drum: Inside / outside cylinder finishing, cylindrical precision grinding machine, drum heating evenly, no color difference.

3. Integrated slip ring: free maintenance

4. Heating tube: Taiwan stainless steel heating tube, heat the conductive oil directly, temperature can raise to 200 ℃ with in 45 minutes.

5. Universal bearing: we use the lasted universal bearing, which can effectively reduce the wear of bearing and reduce the loss of parts.

6. Small machine, proofing and producing, lower cost.

| Roller heat transfer machine | |||

| Model | BB61120 | BB61170 | BB61190 |

| Transfer width | 1200 mm (47'') | 1700 mm (47'') | 1900 mm (74.8") |

| Blanket size | 1250*3480*10 mm | 1750*3480*10 mm | 1950*3480*10 mm |

| heating Power | 32.5 KW | 40.5 KW | 40.5 KW |

| Heating media | Oil | ||

| Voltage | 3 phase 220 V/380 V | ||

| Number of heating elements | 27 | ||

| Diameter of drum | 610 mm | ||

| transfer speed | 150-450 m/h | ||

| Max. Temperature | 260 ℃ | ||

| Process Path | feeding in through the top of drum | ||

| Blanket separation method | manual | ||

| Sensor adjust the Blanket device | no | ||

| Function of roll-to-roll | yes | ||

| Function of piece-by piece | yes | ||

| Number of feeding rollers | 3 | ||

| Number of collection rollers | 2 | ||

| Number of air shaft | 2 | ||

| worktable | yes, without glass | ||

| Air compressor | needed, 1 P, (not include) | ||

| machine weight | 1900 KG | 2100 KG | 2400 KG |

| Worktable size | 3.5*1.55*1.2 m | 3.5*1.88*1.2 m | 3.5*2.05*1.2 m |