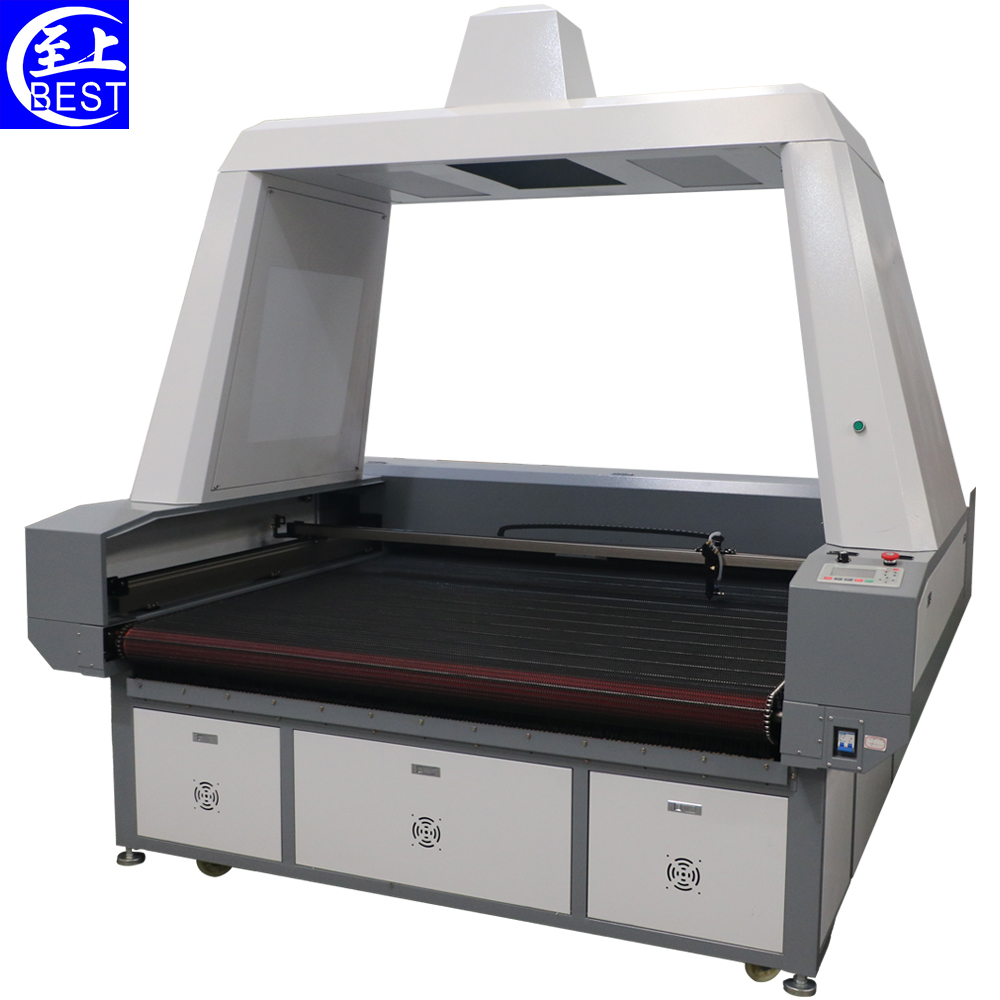

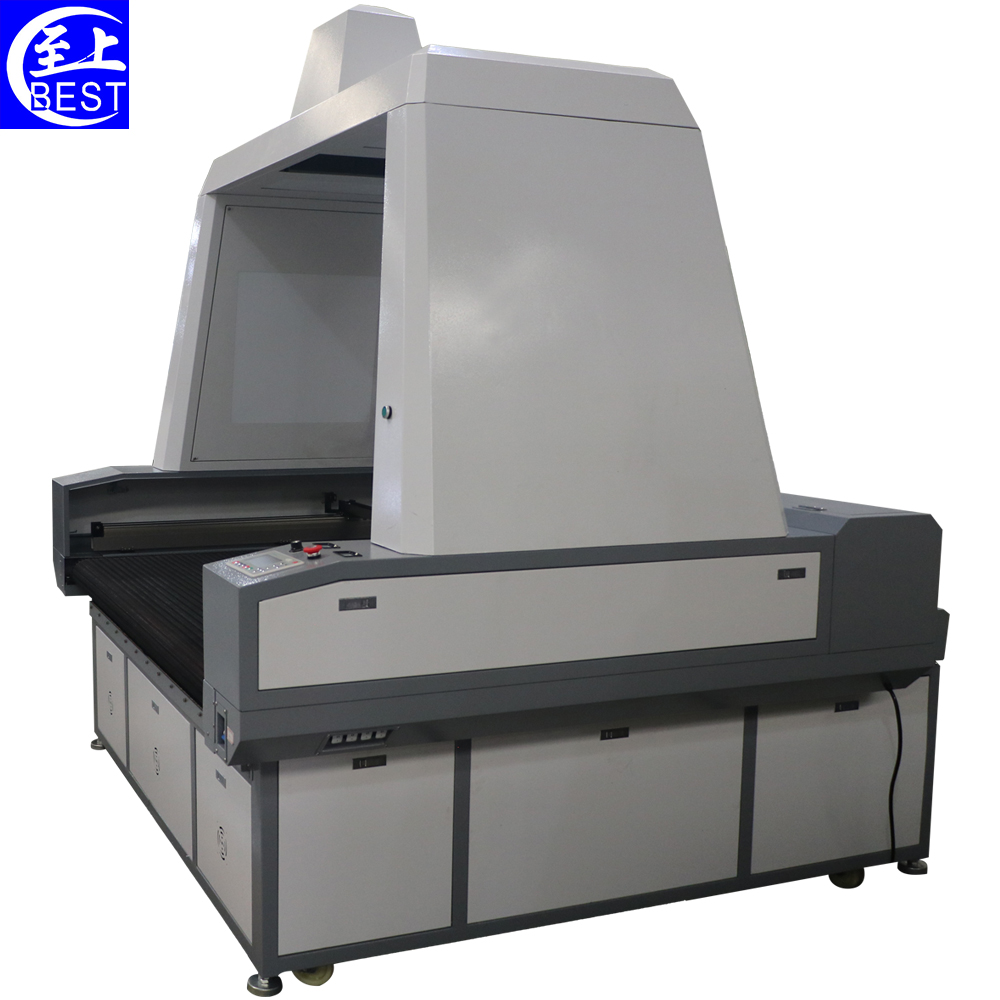

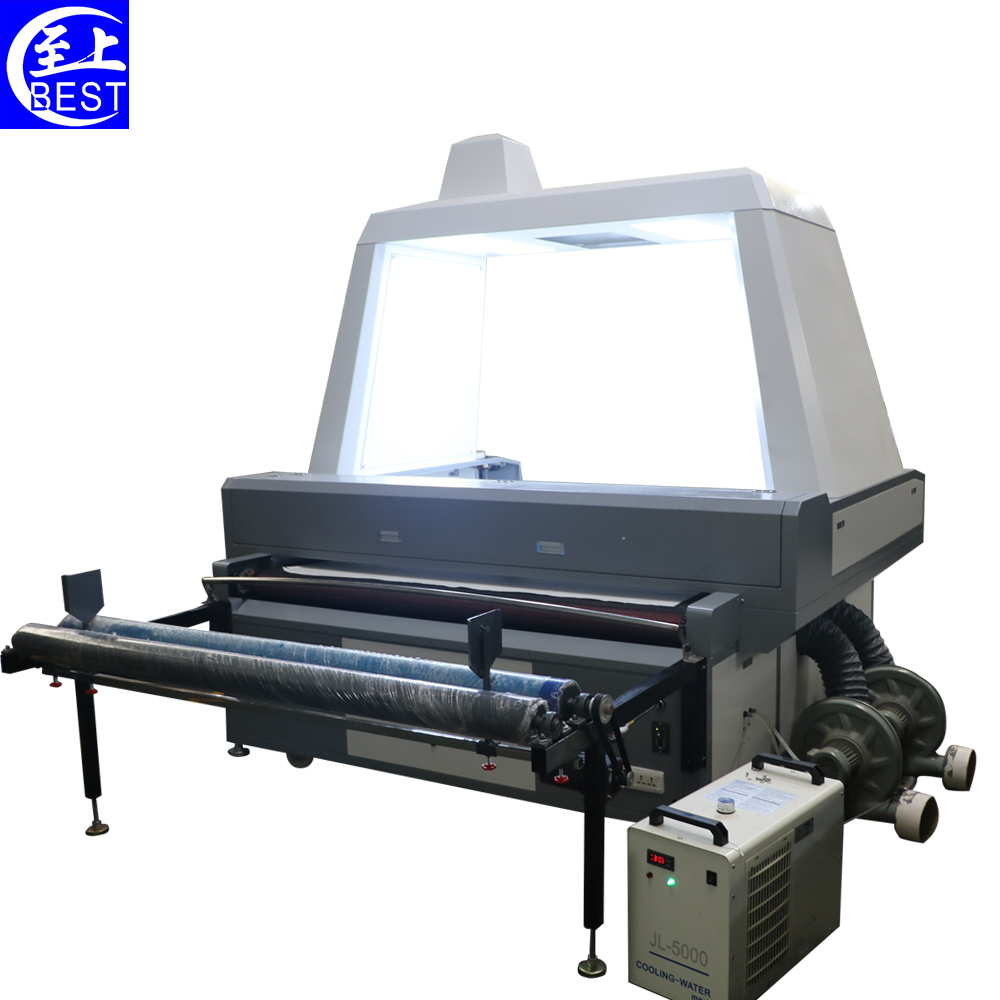

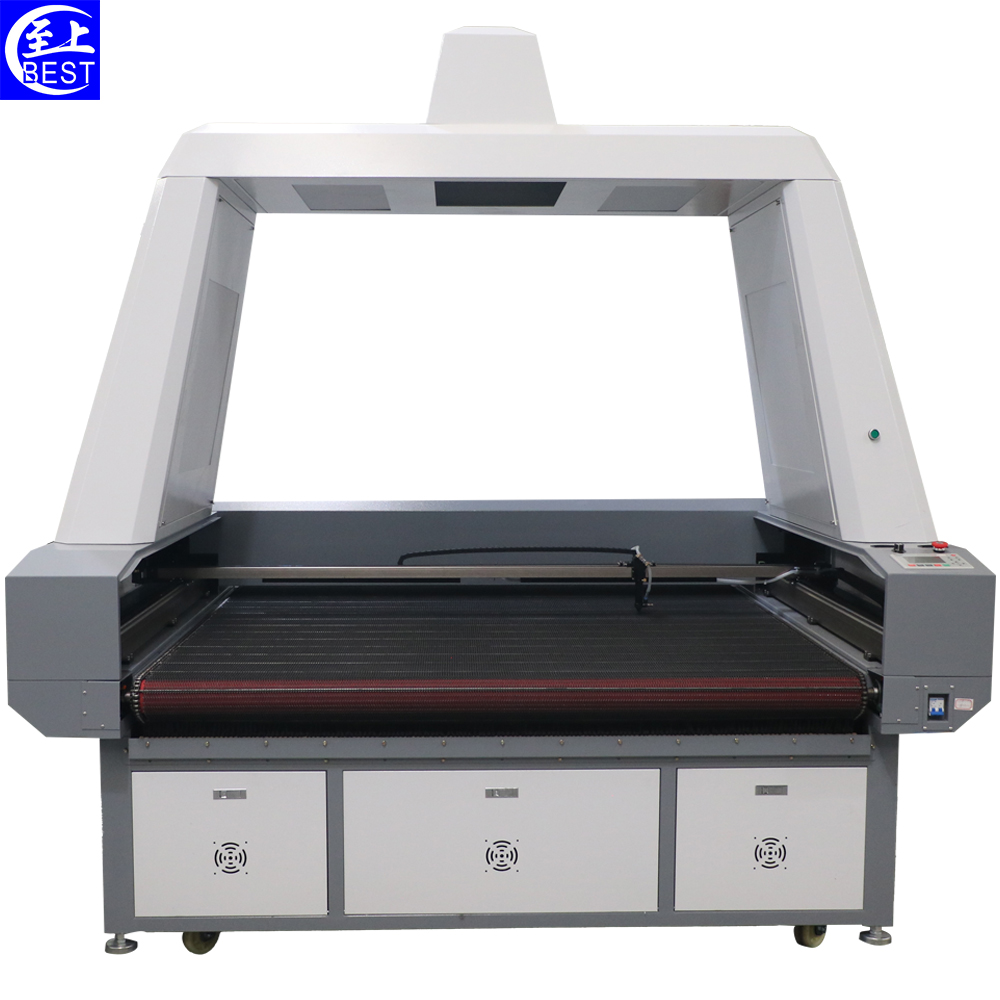

1 Applying Canon HD SLR camera, can use for dealing with 1.8 m big pattern, and cut along the fabric or leather edge, which can solve the problem cause by fabric and leather deformation and stretching, thus ensuring the precision of machine cutting

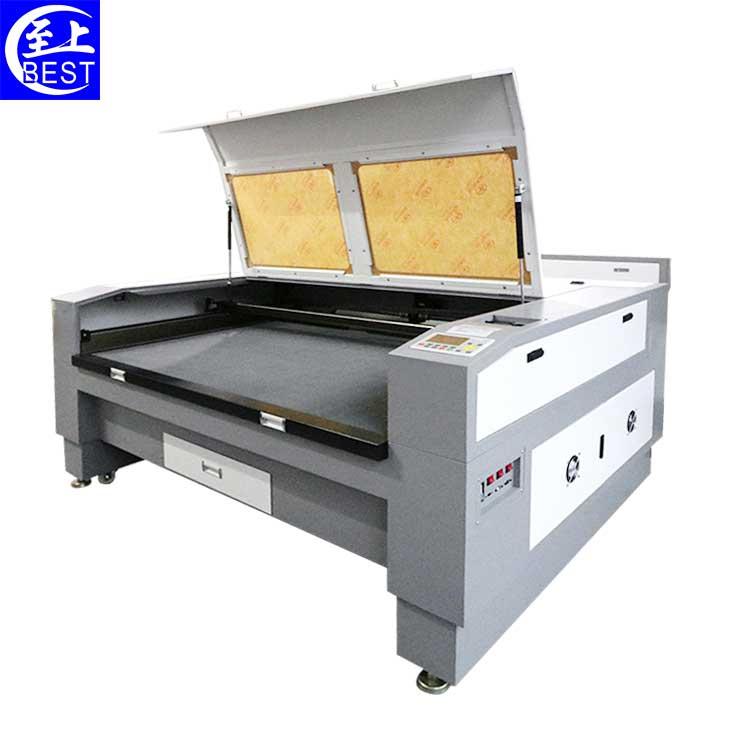

2 Imported Precision slider, High-speed and stable operation

3 Imported belts, there are 15 strips steel wires inside, have good flexibility and hard to be out of shape.

4 Lightweight laser head, move flexibly and fast

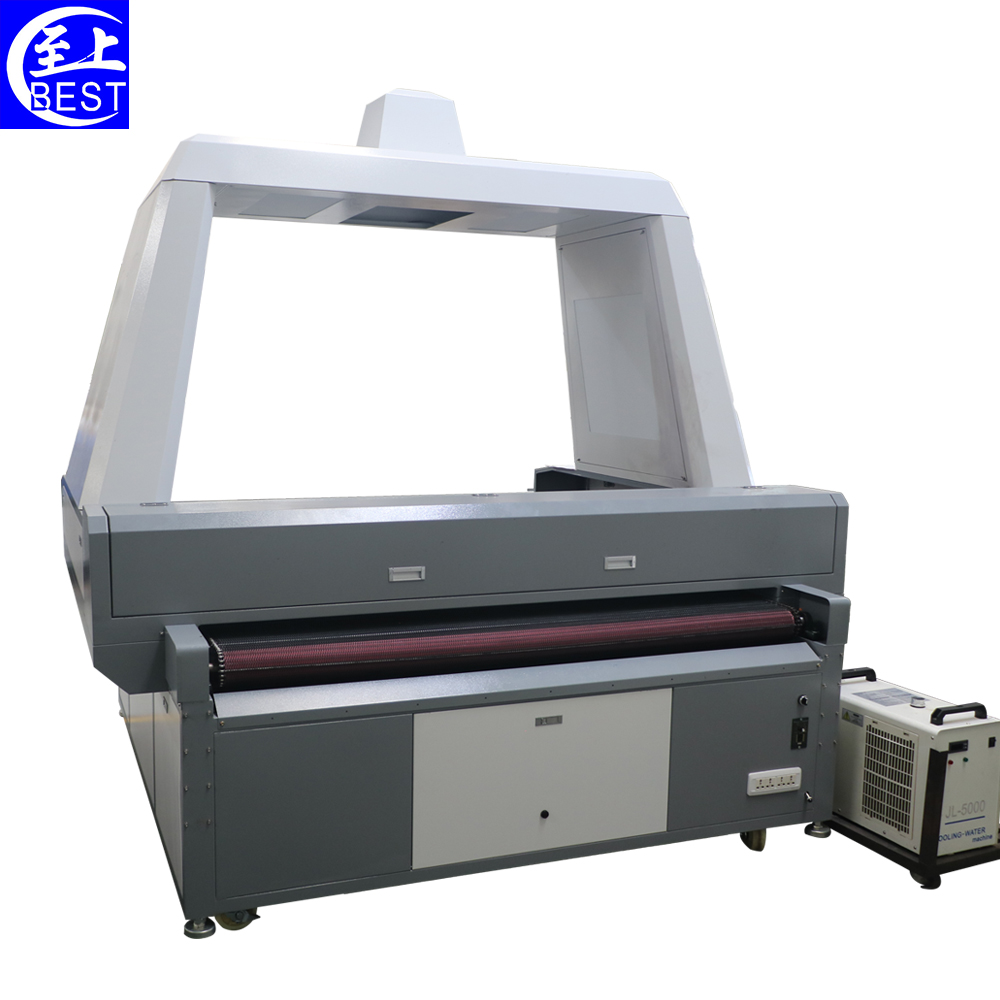

5 The device of automatic feeding and rolling materials, significantly increase productivity

6 Applying imported high-performance AC servo motor. The machine runs stably, precisely and fast.

7 Lightweight system, saves space and easy to operate.

Dedicated high-performance laser tube with the perfect optical system and stable laser power.

8 After machine painted, two gantry milling machine milling flat work surface to make precision reach±0.01mm, ensure that within 10 years of machine tool will not appear laser path deviation and make the machine more durable.

9 The camera on the top of machine will captures all patterns on the worktable one time, then with the help of applicable software, the patterns photo will be input into the computer, after DSP processing it, the machine will locate the pattern edge, thus the laser head will cut materials alone the edge of patterns.